MCPCB (Metal Clad Printed Circuit Board) technology was initially designed in the 60's for high power applications. Known also as MPCB (Metal Printed Circuit Boards) or IMS (Insulated Metal Substrate). Since then it has been used widely in the LED industry, where the benefits of reduced junction temperatures have been realised.

The advantage of using metal clad material for PCB production as opposed to more traditional materials such as FR4 is simply to do with the efficient removal of heat. The dielectric insulating material in metal-clad materials is designed to have a much superior thermal conductivity than that of FR4—generally ranging from 1W/m-K to 9W/m-K. Allowing for efficient heat removal.

The material used to fabricate metal-clad PCBs is made of 3 parts; The base layer, the dielectric, and the copper foil -

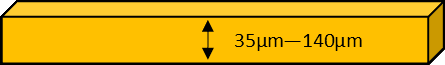

This is the top copper layer of the material that will eventually be processed into the electrical conductors as per conventional PCBs. Generally, 1oz-4oz but can be greater.

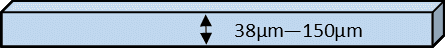

This is the key part. This is the substance that electrically isolates the Aluminium base layer from the copper foil but also allows for rapid heat transfer between the two. It ensures that the heat generated in the components is dispersed to the heat sink as quickly as possible and determines the materials thermal properties. This is the ingredient of the substrate that sets apart a world-class material from the cheaper alternatives on the market.

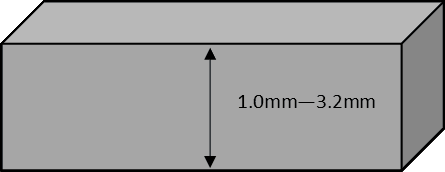

In the vast majority of cases the base layer is aluminium, generally 1mm-3.2mm thick (most commonly 1.6mm). Aluminium is a very efficient conductor of heat and as such is perfect for applications involving rapid heat transfer.